Polarizing cubes

Main features

- Optically contacted or epoxy glued configurations available

- Minor transmitted beam deviation (<3 arcmin)

- Anti-reflective coated input and output faces

Application examples

- Beam separation and combining by polarization

- Polarization separation

- Description

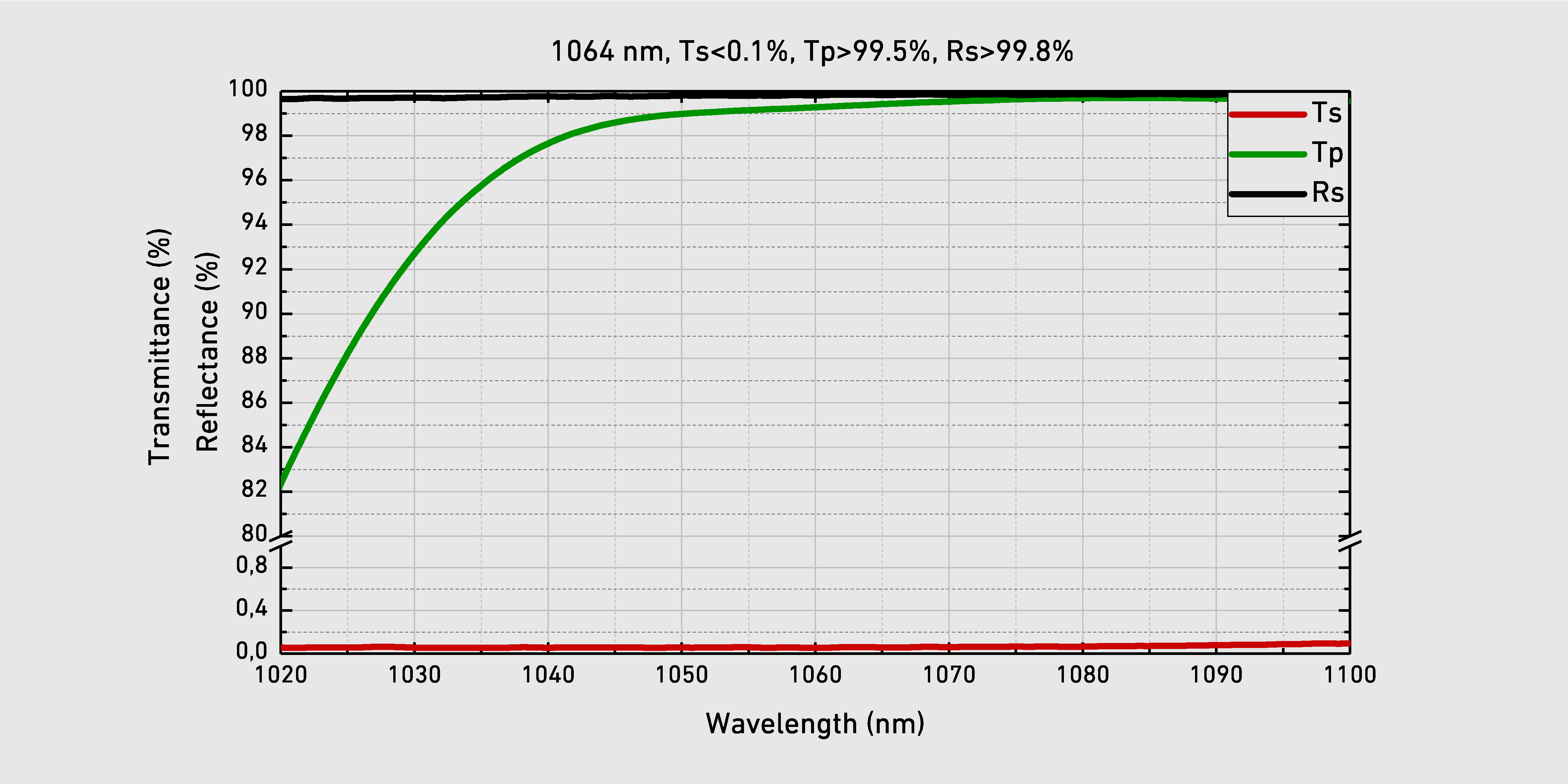

- Curves

- Specifications

4Lasers unmounted polarizing cubes are fabricated from two identical right-angle prisms with their hypotenuse faces adhered together via optical contact or epoxy glue. Polarized cubes are designed to transmit p-polarized light with minor deviation (<3 arcmin) and deflect s-polarized light by 90° angle. Prior to cementing polarizing dielectric thin-film coating is applied onto one of the prisms hypotenuse faces, while input and exit surfaces are anti-reflective coated for a particular wavelength range. 4Lasers optically contacted polarizing cubes provide a higher laser-induced damage threshold, therefore are primarily used for high-power applications, while epoxy glued cubes are a cost-effective choice for low and mid-power applications. We recommend using these elements with collimated laser beams in order to avoid beam aberrations.

| Polarizing cubes | |

|---|---|

| Beam deviation | <3 arcmin |

| Clear aperture | >85% |

| Dimensions tolerance | +0,0/-0,2 mm |

| Thickness tolerance | ±0,25 mm |

| Protective chamfers | <0,35 mm at 45° |

| Coatings | Hypotenuse face: polarization beam splitting coating Input and output faces: antireflective coatings |

| Surface quality | 40-20 S-D |

| Surface flatness | <λ/4@632,8 nm |

| Laser-induced damage threshold | >15 J/cm2@1064 nm, 10 ns (for 1025-1080 nm optically contacted cubes) >0,1 J/cm2@532 nm, 10 ns (for 400-700 nm epoxy glued cubes) |

| Mount | Unmounted, available upon request |